how to conduct burn test

Imagine standing in your living room, holding a mysterious swatch of fabric. You’re curious—what is this made of? The material feels familiar, like something our ancestors used to figure out what they had.

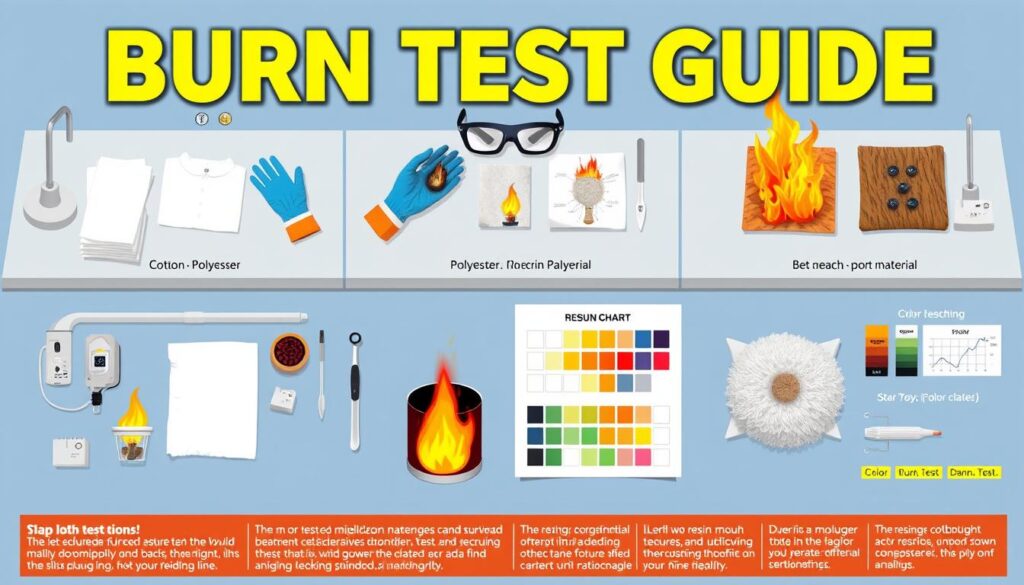

Burn testing is an old method that still works today. It connects us to our past and helps us understand the materials around us. By using flames, we can tell what fabric is made of.

Learning how to conduct a burn test is more than just a task. It’s a way to explore and discover. This burn test tutorial is for anyone interested in fabrics. You’ll learn how to do it safely and accurately.

Key Takeaways

- Understand the fundamental steps on how to conduct a burn test effectively.

- Learn the critical safety measures to prevent accidents during your burn test tutorial.

- Identify different types of fibers accurately through practical observation.

- Gain insights into the importance of monitoring fabric reactions to ensure precision.

- Recognize the value of setting up a proper testing environment for the best results.

Understanding the Burn Test Technique

The burn test technique is a top choice for figuring out what fabrics are made of. It shows us the material’s properties and helps us know how to use and care for it. By doing a burn test, you can find out what fibers are in your fabric. This makes sure the material is real and helps avoid expensive mistakes.

What is a Burn Test?

A burn test is when you light a small piece of fabric on fire and watch how it burns. You need to pay attention to how fast it burns, what it smells like, the type of flame, and what ash is left. These things tell you what kind of fibers are in the fabric.

Why Conduct a Burn Test?

Burn tests are key in many fields, like making textiles, designing, and safety. They’re a simple way to figure out what fabrics are and what they’re made of. They also show if the fabric has special treatments that change how it burns.

Key Benefits of Burn Testing Fabrics

Burn testing has many advantages. It helps us know exactly what fabric we have, which is important for using and caring for it right. It also makes sure the fabric is genuine, which improves the quality of the product. By looking at how fast it burns, what it smells like, and the ash left, we can tell if it’s cotton, polyester, silk, wool, or something else. This helps designers and makers pick the best materials for their projects, making sure they last and are safe.

Essential Preparations for a Burn Test

To have a successful burn test, you need to plan carefully and follow safety rules. This careful preparation makes your burn test more accurate and safe. Here are the key steps to follow.

Gathering Your Materials

First, gather all the things you need for your burn test. You’ll need a flame source like a lighter or match, tweezers for holding fabric, and a fireproof dish to catch any debris. Each item is crucial for a safe test, avoiding accidents and wrong results.

Choosing the Right Test Area

Next, pick a good place for your burn test. Choose an outdoor or well-ventilated indoor area for good airflow and to avoid smoke inhalation. Make sure the area is away from flammable things and drafts. The right location is key for a controlled and safe test.

Safety Precautions

Always put safety first during the burn test. Keep water or a fire extinguisher nearby to handle any fires. Wear non-flammable gloves and keep long hair or loose clothes away from the flame. These steps help make your burn test safe and effective.

By carefully choosing materials, a test area, and following safety rules, you set up for a successful burn test. This focus on detail ensures your test is productive and safe, giving you reliable results for your fabric burn test.

| Material | Occurrence Rate | Fiber Type | Burning Characteristics | Smell | Residue |

|---|---|---|---|---|---|

| Cotton | 1 | Natural (Plant) | Steady burn with clear flame and afterglow. | Smells like burning paper or wood. | Leaves very little ash. |

| Silk | 1 | Natural (Animal) | Burns slowly and self-extinguishes. | Smells like burning hair. | Brittle residue that can be crushed. |

| Wool | 1 | Natural (Animal) | Burns slowly and self-extinguishes. | Smells like burning hair. | Large, brittle beads that can be crushed. |

| Tencel | 1 | Man-made (Wood) | Steady burn with yellow flame. | Smells like burning wood. | Leaves gray ash. |

| Acetate | 1 | Synthetic | Burns rapidly while melting. | May smell like vinegar. | Hard, dark bead that can’t be crushed. |

| Nylon | 1 | Synthetic | Stops burning, melts. | May smell like plastic or celery. | Hard, dark bead that can’t be crushed. |

| Polyester | 1 | Synthetic | Burns slowly while shrinking from the flame. | May smell like a sweet chemical. | Hard, dark bead that can’t be crushed. |

| Acrylic | 1 | Synthetic | Burns rapidly while melting. | May smell like a chemical. | Hard, black bead that can’t be crushed. |

Materials Required for Performing Burn Test

To do a burn test right, you need certain tools for safety and accuracy. Here’s a guide on what you need and how to stay safe while doing it.

Flame Source

You’ll first need a good flame source. A lighter or candle works well. It should burn steadily and be easy to control. This helps you see how the fabric burns safely and gets the same results every time.

Tweezers and Fireproof Dish

Then, get tweezers for handling small fabric pieces safely. Metal tweezers are best. Also, have a fireproof dish ready to catch any spills or drips. This is key to avoid fires spreading.

Ventilated Area and Safety Measures

Do the test in a place with good air flow to clear out smoke and fumes. This keeps you safe from harmful gases. Always have a fire extinguisher or water nearby for emergencies.

Step-by-Step Burn Test Procedure

Conducting a burn test can reveal valuable insights into the composition of different fabrics. Follow this detailed burn test guide to get accurate results. Ensure you carefully proceed through each step to achieve consistency and safety.

Preparing the Fabric Swatch

Start by preparing a small piece of the fabric you wish to test. The swatch should be manageable and fit well within your tweezers to avoid any accidental drops. Make sure to select a representative sample, especially if testing a patterned fabric.

Lighting Your Flame Source

Next, light your flame source with care, ensuring it is stable and won’t easily tip over. A steady flame helps in observing the fabric’s reaction accurately. Safety is paramount, so always conduct the burn test in a well-ventilated area away from flammable materials.

Observing the Fabric’s Reaction

Bring the fabric swatch close to the flame and observe its behavior meticulously. Each type of fiber—animal, cellulose, or synthetic—exhibits distinct reactions when burnt. Does the fabric melt, burn quickly, or drip? What kind of smoke is produced? Does it smell like burning hair, paper, or plastic? The ash residue is another key indicator: does it turn into powder, bead up, or form hard strings?

| Type of Fiber | Reaction to Flame | Smoke and Smell | Ash Residue |

|---|---|---|---|

| Animal Fibers (Wool, Silk) | Slow to ignite, self-extinguishes | Burning hair scent | Beads up, crushes easily |

| Cellulose Fibers (Cotton, Linen, Viscose) | Catches fire quickly, burns brightly | Burnt paper scent | Powdery ashes |

| Synthetic Fibers (Polyester, Nylon, Acrylic) | Curls away, melts, may drip | Chemical, sweet, or vinegar scent | Hard strings or beads |

By following these burn test steps, you will be able to identify various fabric types accurately. Each observation helps determine the fiber composition, making your conducting burn test both informative and efficient.

Identifying Different Types of Fibers

It’s important to know how to tell apart different fibers through a burn test. Each type of fiber reacts differently when it’s exposed to fire. Here’s how to spot animal, cellulose, and synthetic fibers.

Animal Fibers: Wool and Silk

Wool and silk burn slowly. They stop burning when you take away the flame. These fibers smell like burnt hair or feathers and leave soft ashes.

These ashes can be crushed easily between your fingers. This is key to identifying them.

Cellulose Fibers: Cotton, Linen, and Viscose

Cotton, linen, and viscose catch fire quickly and burn brightly. They leave soft, powdery ashes behind. The smell of burning cellulose is like burning paper.

Cotton has a glow after it burns out. Linen burns slowly but has similar traits.

Synthetic Fibers: Polyester, Nylon, and Acrylic

Synthetic fibers like polyester, nylon, and acrylic act like plastic when on fire. They melt and can form long strings or drip. Polyester and nylon smell sweet when burned.

Acrylic smells like vinegar. They create dark smoke with a chemical smell. Knowing these signs helps identify synthetic fibers.

Analyzing Burn Test Results

When you analyze burn test results, look closely at flame behavior, smoke, smell, and ash. These details can tell you a lot about the fabric’s fibers.

Flame Characteristics

Fabric’s fire behavior can show its fiber type. Wool and silk burn slowly and stop when removed from the flame. They smell like burnt hair and leave easy-to-crush beads.

Cotton, linen, and viscose burn fast and brightly. They leave powdery ash and smell like burnt paper. Polyester and acrylic curl away, melt, and form strings or beads. They smell sweet when burned.

Smoke and Smell

The smoke and smell during the burn test are key. Cotton and cellulose fibers make light white smoke that smells like burnt paper. Animal fibers produce darker smoke with a strong burnt hair smell.

Synthetic fibers like polyester and nylon smell sweet. Acetate and acrylic smell vinegary.

Ash Residue

The ash left after burning also tells you about the fabric. Animal fibers leave hard, beady ash that turns to black powder easily. Cellulose fibers make fine, powdery, light ash.

Synthetics leave sticky or hard residue, looking like melted plastic. Knowing these differences helps identify fabric types.

Here’s a table to help you understand these differences:

| Fabric Type | Burn Characteristics | Residue | Odor |

|---|---|---|---|

| Animal Fibers | Slow burn, self-extinguishes | Beady, crushable ash | Burnt hair |

| Cellulose Fibers | Quick ignition, bright flame | Powdery, light ash | Burnt paper |

| Synthetic Fibers | Curls away, melts | Hard or sticky ash | Chemical smell |

For more detailed guidance on conducting a burn test, check out this comprehensive guide.

Comparing Single and Blended Fabrics

Doing a burn test on single and blended fabrics can show us a lot. It helps us figure out what they’re made of. When we test blended fabrics, we see how different fibers work together. This tells us about the mix and the types of fibers used.

This guide shows how cotton and polyester mix in a burn test. Cotton lights up fast with a yellow flame. It makes white smoke and dark gray ash. Polyester, on the other hand, shrinks, melts, and makes black smoke with a hard bead.

Knowing these differences is key when talking to fabric suppliers. It helps us understand what we’re working with. This makes it easier to talk about fabrics and helps us make quicker decisions.

Here’s a table showing how different single fabrics react in a burn test:

| Fabric | Reaction to Flame | Smoke | Ash/Residue |

|---|---|---|---|

| Cotton | Ignites quickly, yellow flame | White smoke | Dark gray ash |

| Rayon | Ignites rapidly, yellow flame | No smoke | Light gray ash |

| Acrylic | Shrinks, burns slowly | Black smoke | Yellow-brown irregular ash |

| Polyester | Shrinks, melts, burns slowly | Black smoke | Round, hard black bead residue |

| Nylon | Shrinks, melts, burns slowly | Black smoke | Hard black beads, celery-like odor |

When testing blended fabrics, it’s important to burn both the warp and weft yarns. This way, we can really know what the fabric is made of. Knowing how each part reacts helps us judge the fabric’s quality and how to care for it.

Having a collection of fabric samples to compare and practicing identifying fabrics by touch and look can improve your skills. It makes you better at figuring out what fabrics are.

Common Mistakes to Avoid in Burn Testing

Burn testing can help identify different fibers. But, it’s important to avoid common mistakes to get accurate results. Here are some key errors to watch out for.

Using Inadequate Equipment

One big mistake is using the wrong equipment. Make sure your flame source, like a candle or lighter, has a steady flame. You’ll also need tweezers to hold the fabric and a fireproof dish for safety.

The fabric swatches should be about 2 x 3 inches. This size is big enough for a reliable test. Using high-quality tools is key to getting accurate results.

Overlooking Safety Precautions

Safety is always first when doing a burn test. Do the test in a well-ventilated area to avoid harmful fumes. Keep a fire extinguisher or a bucket of water nearby, just in case.

Wear heat-resistant gloves and safety glasses to protect yourself. Never skip safety steps to ensure a safe test.

Misinterpreting Results

Another mistake is not understanding the test results. Different fibers react differently to fire. For example, animal fibers like wool and silk might char and smell like burnt hair.

Cotton fibers ignite quickly and smell like burnt paper. Synthetic fibers may curl, melt, or drip and smell chemical. Not knowing these differences can lead to wrong conclusions about the fabric.

For fabric blends, look at how the different fibers react together. Paying close attention to these details will help you get more accurate results.

FAQ

What is the purpose of a burn test in fabric identification?

What materials do I need to conduct a burn test?

How should I prepare for a burn test?

How do different types of fibers react in a burn test?

What safety precautions should I take during a burn test?

How do I analyze the results of a burn test?

Can burn tests identify blended fabrics?

What are common mistakes to avoid during burn testing?

- Fragrance That Wows: A Beginner’s Guide to Adding Scents to Your Homemade Candles

- best essential oils for candles

- wood wick guide

- how to make candles smell stronger

- how to ship candles

- how to fix soy wax frosting

- wick Guide how to choose the right wick size with chart

- how to make candle molds

- how to clean candle wax

- how to reuse candle jars

- soy wax candle troubleshooting

- best wax melter for candle making

- how to conduct burn test

- why candle flickering crackling smoking

- how much wax per candle

- how to make candles smell stronger

- Easy Ways to Increase the Scent Throw of Your DIY Candles

- How to Make Candles for Meditation and Relaxation

- Using Upcycled Materials in Candle Making

- How to Make Hand-Poured Candles: Tips and Techniques

Leave a Reply